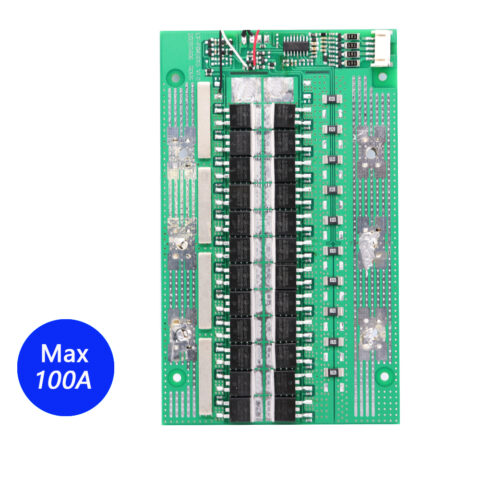

LT 12V 100A BMS for 4S Lifepo4 Battery Power

4S 12V LiFePO4 Battery BMS 100A with NTC Thermal Sensor, it can support the same battery packs in series. E.g there are the same 4PCs 12V 100Ah battery packs with our BMS,then you can make a 48V 100Ah Lithium battery pack.

| Model | LT-P04S003 |

| For | Li-ion |

| Series | 4S |

| Continious Discharge Current | 100A |

| Inpulse Current | 400A |

When it comes to BMS assembly, there are several important notices to keep in mind. Here are some key considerations:

- Qualified personnel: BMS assembly should be carried out by qualified personnel who have the necessary knowledge and expertise in building automation systems. They should be familiar with electrical systems, control wiring, and the specific BMS components being used.

- Compliance with regulations: Ensure that the BMS assembly complies with all relevant local building codes, regulations, and safety standards. Adhere to electrical wiring standards and practices to ensure a safe and reliable installation.

- System design and planning: Before assembling the BMS, have a well-thought-out system design and plan in place. This includes identifying the various components, their locations, wiring requirements, and communication interfaces. Consider the integration of different building systems, such as HVAC, lighting, and security, into the BMS.

- Documentation and labeling: Properly document the BMS assembly process, including wiring diagrams, equipment schedules, and component specifications. Label all wiring, devices, and control points clearly for easy identification and troubleshooting in the future.

- Wiring and connections: Pay close attention to the wiring and connections during assembly. Follow the manufacturer’s guidelines and specifications for proper wiring techniques. Ensure that all connections are secure, properly insulated, and free from loose strands or exposed conductors.

- Power and grounding: Implement proper power supply and grounding measures. Ensure that power sources are correctly wired, protected with appropriate circuit breakers or fuses, and adequately sized for the BMS components. Use proper grounding techniques to minimize electrical noise and ensure system stability.

- Testing and commissioning: After assembly, thoroughly test the BMS to ensure its proper functioning. This includes checking the wiring continuity, verifying sensor and actuator operation, and testing the communication between different components. Commission the system according to the manufacturer’s guidelines and perform any required calibration or adjustments.

- Maintenance and documentation: Establish a maintenance plan for the BMS, including regular inspections, preventive maintenance tasks, and software updates. Keep detailed records of maintenance activities, repairs, and any modifications made to the system.

- Training and user support: Provide training to users and facility staff on how to operate and interact with the BMS effectively. Create user manuals and documentation that explain the system’s functionalities, troubleshooting procedures, and recommended practices. Offer ongoing support and assistance to users as needed.

- It’s important to consult the specific manufacturer’s documentation and guidelines for the BMS components you are using, as they may have additional notices and instructions specific to their products.